Обґрунтування програмного забезпечення структурно-параметричної ідентифікації для АСУ процесом крупного дроблення руд

Resumen

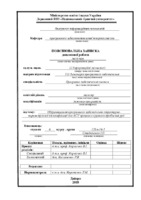

Explanatory slip: 123 р., 19 fig., 2 tables, 4 application, 69 sources.

Object of research: automation of large ore crushing processes management.

The purpose of the degree project: substantiation the use of structuralparametric

method to identify large ore crushing processes, provides an increase in

the accuracy of their models.

Methods of research. At solution of tasks in view the analysis and scientific

generalization of references on initial sending of researches is made, to identify

large ore crushing processes. Composite method of complex control objects

structural-parametric identification was used.

The scientific novelty of the results consists in the method of the composite

structural and parametric identification complicated control facilities to determine

the structure and parameters of processes coarse crushing ores. Also in increasing

the accuracy of determining the structure, estimating and optimizing the

parameters of the model of complex control objects.

The practical value of works consists in developing the software to

implement the structural-parametric identification of large ore crushing processes.

Field of application. The developed method can be used in organizations that

operate complex objects for controlling ore preparation processes (crushing and

grinding).

The economic benefit of operation outcomes implantation is expected at the

expense of increasing the efficiency of large ore crushing processes identification,

which helps reduce operating costs in the operation of complex control objects.

Value of work and summary. The developed technique allows to increase

the efficiency of large ore crushing processes identification through the use of

structural-parametric identification methods.

The prognoses on development of researches. Research of large ore

crushing processes on structural-parametric identification methods allow for the

definition of a rational operating conditions, as well as opportunities to optimize

the complex control objects parameters.